+13

More

Features & Details

- Direct Drive Motor: The mini metal lathe machine adopts a direct drive motor, no belt drive, and no need to replace the belt. 800W brushless motor that provides more power and avoids the need for brush replacements, saving time and effort.

- Built to Last: The mini metal lathe is built to last with high-quality HT200 cast iron. They come equipped with wear-resistant and strong metal gears and aluminum alloy handwheels, ensuring a longer service life.

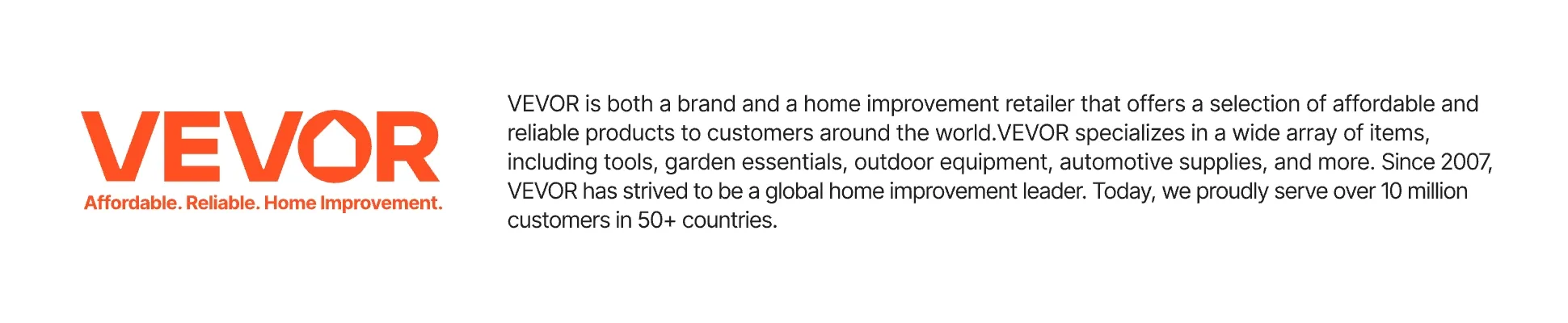

- Continuously Variable: Features a spindle that can turn in both forward and reverse directions with 150-2500 RPM continuously variable speed range. It also has intelligent electric speed controls and a digital display, allowing for convenient data reading.

- Widely Used: 7'' x 16'' metal lathe machine can be used for processing precision parts and models. A wide range of turning pitches can create 19 kinds of threads, 9 kinds of the metric system (0.5-3 mm), and 10 kinds of the imperial system (10-44 TPI).

- Security Comes First: Our power metal lathes have multiple security features in case of emergency, ensuring operator security. These include an emergency stop switch, overload protection, chuck cover power off switch, and a main control panel security switch.

Frequently Bought Together

Reviews 0.0

All reviews are from verified purchases

Average rating based on 0 reviews

Reviews 0.0

All reviews are from verified purchases

See all 0 reviews

About this item

Product specification

- Model

- MX-S716G

- Main Material

- HT200 Cast Iron

- Lifespan

- 3 Years

- Spindle Speed

- 150-2500 RPM

- Hole Through Spindle Diameter

- 32 mm / 1.26 in

- Spindle Taper

- MT4

- Tail Stock Taper

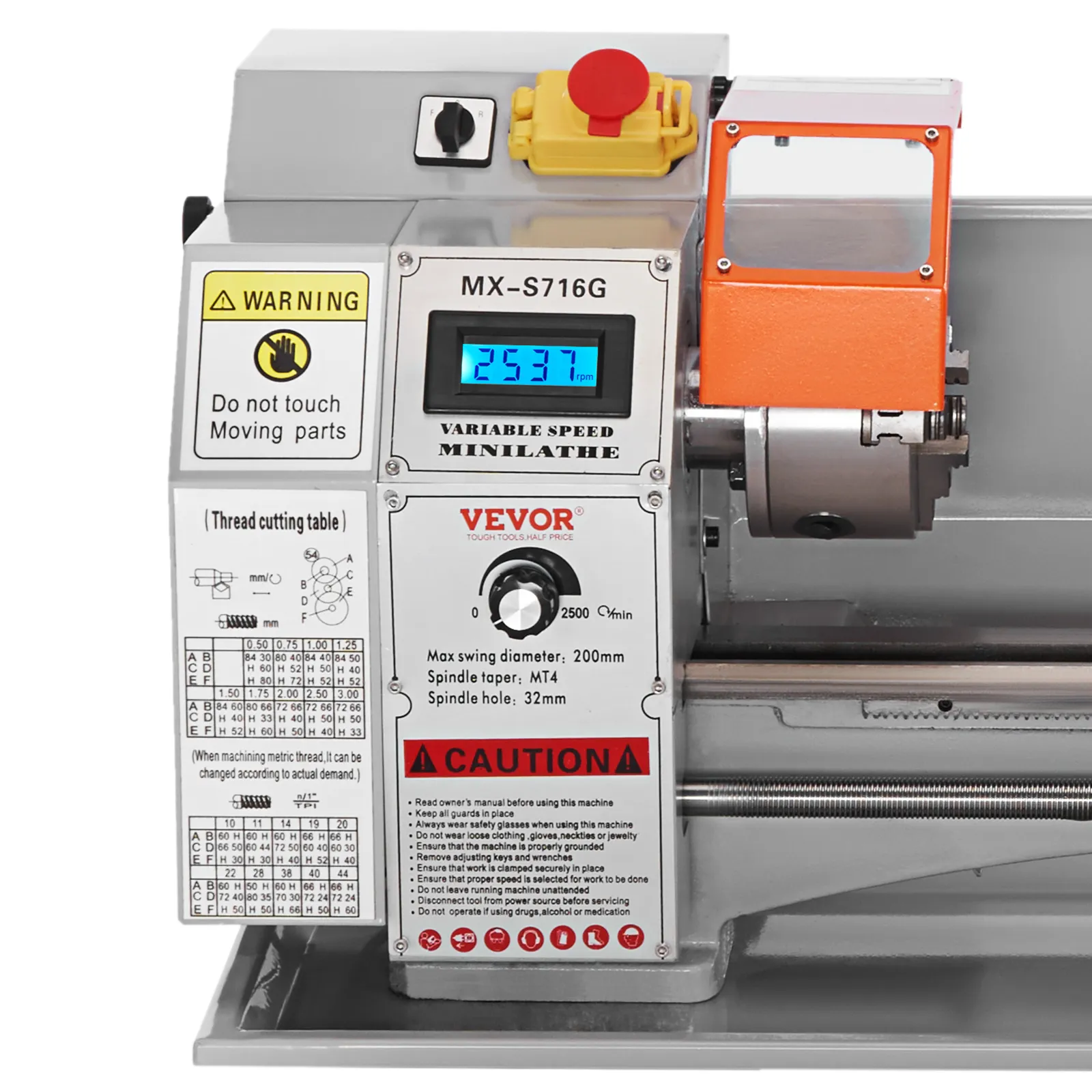

- MT2

- Motor Power

- 800W

- Voltage

- 220V, 50 Hz

- Chuck Diameter

- 100 mm / 3.93 in

- Net Weight

- 39 kg / 85.98 lbs

- Product Dimensions(L x W x H)

- 800 x 340 x 360 mm / 31.5 x 13.4 x 14.2 in

Description

Direct Drive Motor Mini Metal Lathe

Are you ready to get more done? Our mini metal lathe measures 7 in x 16 in and features an 800W direct drive motor, no maintenance, and no belt drive. VEVOR benchtop metal lathe is specifically designed for creating complex and precise parts, simple to operate even for the novice.

Key Features

Protection Devices

Our mini metal lathe machine is designed with a probe window-type shield and power-off protection, ensuring more secure processing.

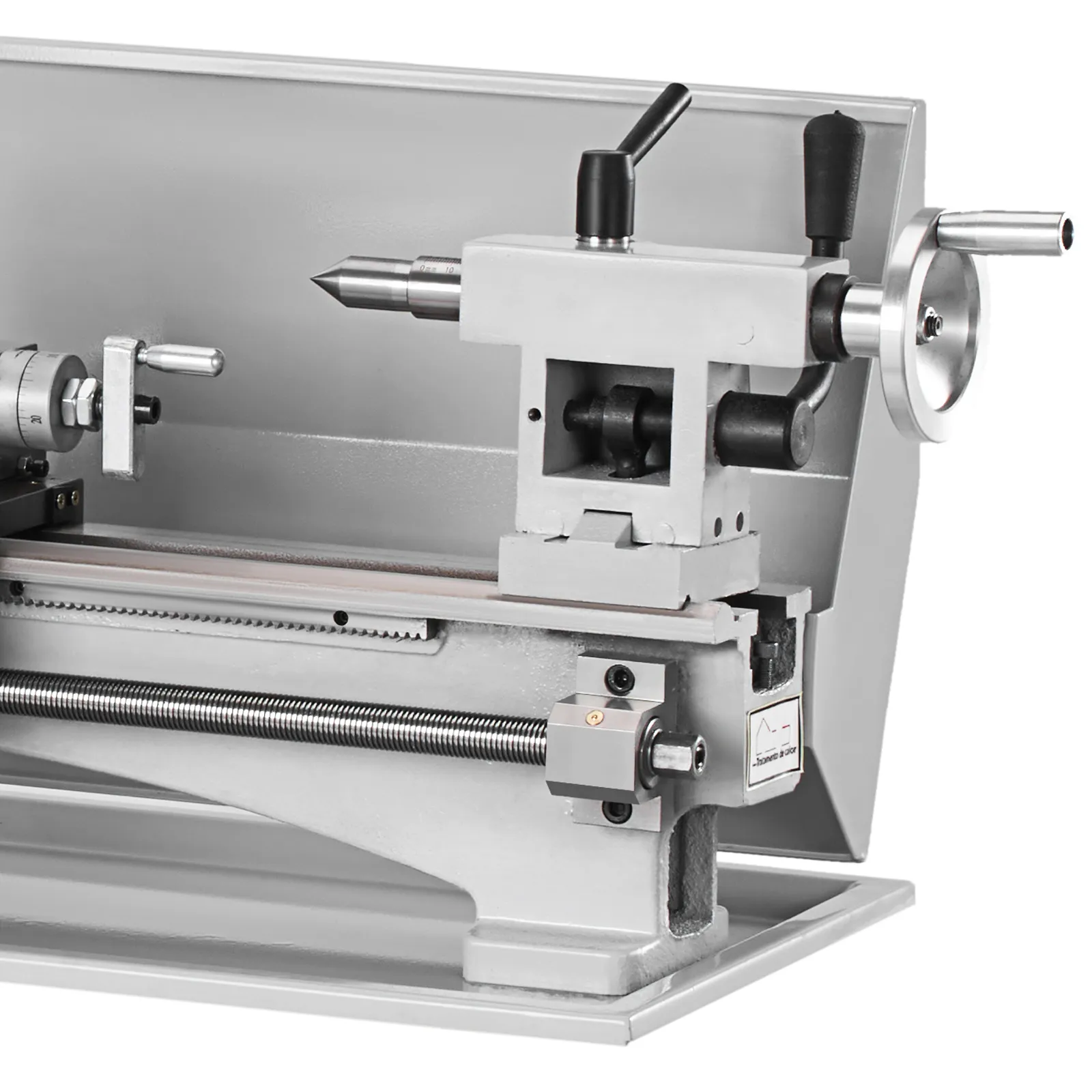

Aluminum Alloy Handwheel

The aluminum alloy handwheel is equipped with a high-precision scale for easy operation and is designed to create complex and fine parts.

Automatic Feed Screw

The V-shaped precision steel guide with the automatic feed screw and high strength ensures the parallelism of the main axis and lathe body.

Product guides and documents

User manual-en (PDF) Review

Questions and Answers (5)

Hello,

Could you please tell me the key differences between this lathe and the one found at https://m.vevor.com.au/metal-lathe-c_10121/mini-lathe-machine-8-x14-650w-210x350mm-metalworking-lathe-small-metal-lathe-p_010962137821 as I'm not quite clear on the reason for the price difference.

Thank you,

Eugene

Their parameters are different. 7 '' x 16 '' does not require a belt, it does not have a belt drive and is a brushless motor. 8x14 is a regular brush motor.

By vevor

Helpful

(

6

)

Does this product come with any tooling and what size tooling would fit?

It comes without tools. 10*10mm will be fine.

By vevor

Helpful

(

2

)

Does this lath come with reversible jaws

There are positive jaws and reverse jaws on the chuck.

By vevor

Helpful

(

1

)

Can you advise - the specifications state that the spindle taper is MT5, which should be a spindle bore of ~38mm, however the specifications also state that the spindle bore is 32mm.

Which is correct?

thanks

32mm. Mt4.

By vevor

Helpful

(

1

)

A customer review says that he found that the spindle bore was more like m4 1/2 (a size which isn't used), not the MT4 claimed, which matches with the claimed spindle bore size of 32mm. Can you justify why you've gone with a non-standard spindle size?

This seems an otherwise good size lathe, but non-standard tool sizes are a real deal-breaker.

In order to use the Φ32 through hole, a non-standard spindle taper is used

By vevor

Helpful

(

0

)

BZDMNJSCCSFWSEYI0V3

VEVOR Mini Metal Lathe Machine, 180 x 400 mm, 800W Precision Benchtop Power Metal Lathe, 150-2500 RPM Continuously Variable Speed, with 3-jaw Metal Chuck Tool Box for Processing Precision Parts

0 0 Reviews

AU $ 1,298 99

Earn at least 2% points on purchases or save up to 15%.

FREE to join

Each when you buy 0+.

Shop

Get -% off for new user

Exclusive AU $5.00 off for your first three orders on the App.

Download Now

In Stock

Security & Privacy

100% Secure payment

Secure privacy

FREE Returns

30-day Free Returns

Refund for lost packages / damaged items

Professional Service

12-months warranty

Customer Support

Compare with similar items

Similar Items You Might Like

People Who Bought This Item Also Bought

Best sellers in this category

People Who Viewed This Item Also Viewed

Your Browsing History

Recommended Searches

construction near me electrical tools and equipment electronic tools and equipment best steel for house construction car electrical repair shops steel construction 8 x 10 inch frame in cm 10 x 15 frame measuring tools and equipment woodworking tools near me 40 x 40 frame 36 x 36 frame 18 x 24 inch frame in cm electrical engineering tools 20 x 30 inch frame 13 x 13 frame 18 x 20 frame 12 x 16 inch frame 24 x 36 inch frame 12 x 18 inch frame