Tough Equipment & Tools, Pay Less

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

Why Choose VEVOR?

- Premium Tough Quality

- Incredibly Low Prices

- Fast & Secure Delivery

- 30-Day Free Returns

- 24/7 Attentive Service

Tough Equipment & Tools, Pay Less

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

Why Choose VEVOR?

- Premium Tough Quality

- Incredibly Low Prices

- Fast & Secure Delivery

- 30-Day Free Returns

- 24/7 Attentive Service

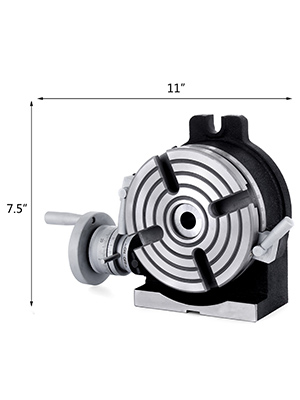

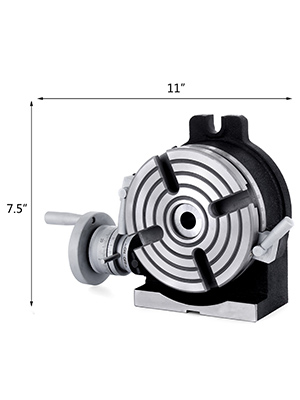

150mm / 5.9" Vertical & Horizontal Rotary Table

The vertical & horizontal rotary table, one of the main accessories of the milling machine, is a precision work positioning device. This machine is widely used in metalworking, enabling the operator to drill or cut work at exact intervals around a fixed axis.

- Vertical & Horizontal Position

- Fantastic Material

- Excellent Precision

- Convenient to Adjust

- Wide Application

Vertical & Horizontal Design

It can be mounted "flat," with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. Or, mounted the rotary table on its end (or mount it "flat" on a 90° angle plate) so that it rotates about a horizontal axis. In this configuration, a tail stock can also be used, thus holding the workpiece "between centers."

HT200 Casting

HT200 casting has excellent casting performance, shock absorption performance as well as high strength heat resistance. It ensures the superior performance of the machine and provides you a good sense of use.

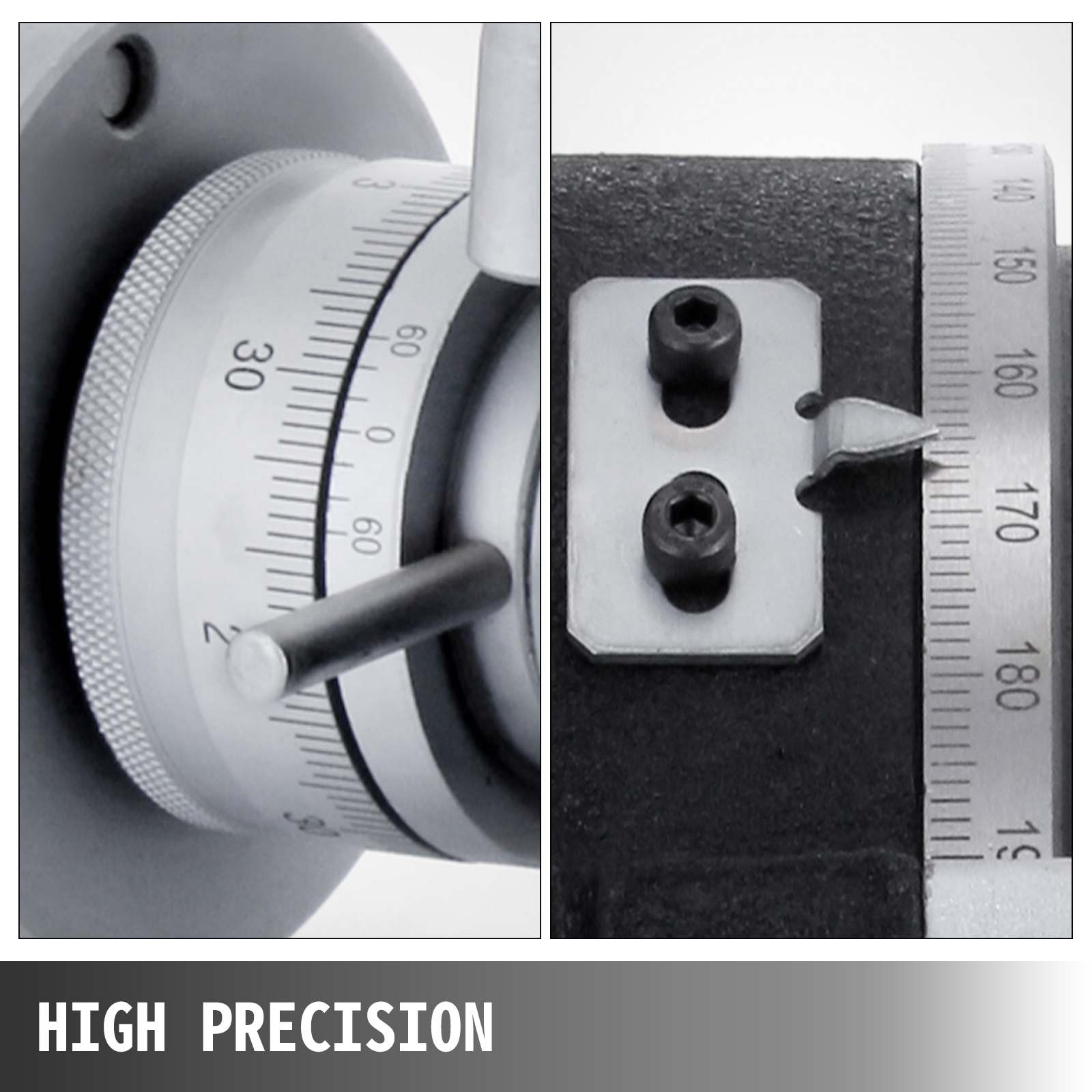

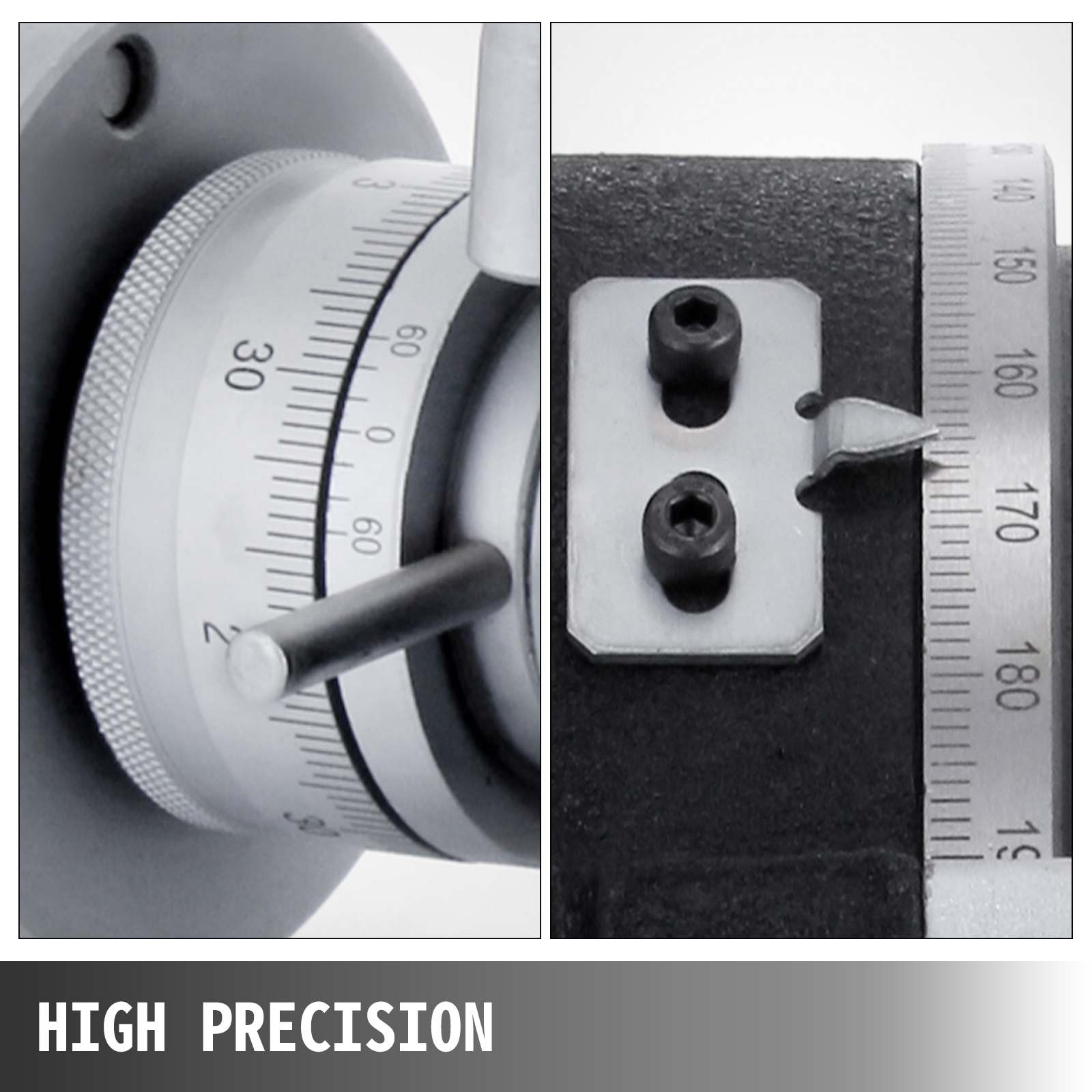

High Precision

The dial is divided into 360 degrees in total. The minimum scale can be accurate to seconds. All of these help you handle more complex and more precise tasks. Spindle end is applied accuracy bearing. Can be assured to keep very steady under load cutting

Easy to Adjust

It's not difficult for you to adjust the rotary table milling machine. What you should do is to adjust the handle to the position where you want because the precise scale is marked on the dial.

Free Accessories

Except for the 5.9''(150 mm) rotary machine table, we also offer you four locating blocks. The center can be corrected quickly and accurately by the Key guide block.

Multiple Use

Widely used in metalworking, enabling the operator to drill or cut work at exact intervals around a fixed axis. Great for circular cutting work, boring, spotfacing, and similar work.

Package Content

- 1 x Vertical and Horizontal Rotary Working Table

Specifications

- Clamping table diameter: 150mm / 5.9"

- Number of grooves: 4

- Width of grooves: 11mm / 0.43"

- Circular Accuracy: 0.04

- The parallelism of the mounting surface: 0.04

- Parts accuracy: 45"

- Transmission of the worm gear: 90/1

- Basic dimension horizontal: 180 x 170mm / 7 x 6.7"

- Basic dimension vertical: 205 x 80mm / 8 x 3.15"

- Height: 80mm / 3.15"

- Weight without packaging: 11.1kg / 24.47lb

- Worktable with scale: 360 °

- Load horiz.: 40kg / 88.18lb

- Stress vertic.: 20kg / 44.09lb

- MK: 2