Welding fire blankets are a must-have piece of safety gear for any welding workspace. They are designed to provide the highest level of protection against heat, sparks, and splatter, and are available in different sizes, materials, and thicknesses to suit any specific needs. With a fire blanket, you can ensure that your workshop is safe and secure, allowing you to focus on the job at hand.

The 05 Best Welding Fire Blankets for 2023: Our Reviews and Recommendations

With the rise of do-it-yourself projects, welding has become an increasingly popular activity for home hobbyists. But with such a high-risk activity, it’s essential to make sure that you’re equipped with the best fire protection possible. That’s why we’ve put together our list of the 05 best welding fire blankets for 2023:

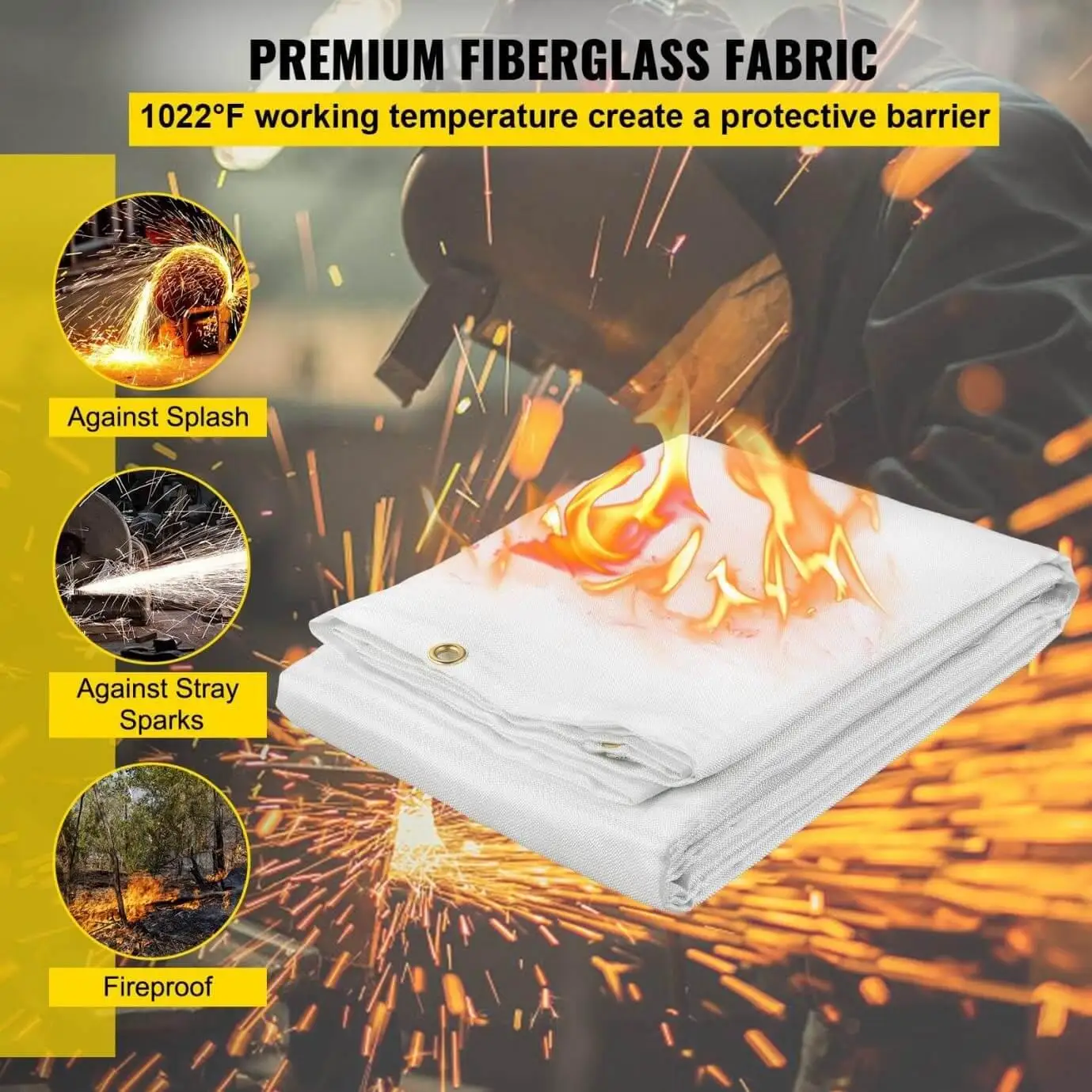

1. VEVOR Fire Blanket

VEVOR Fire Blankets are designed to provide superior thermal protection for welding and other high-Heat applications.

Looking to stay safe and prepared? Look no further than the VEVOR firefighting equipment. And the best part? You can take advantage of the “VEVOR MONTHLYDY PROECIS” Campaign and get your own gear today!

Specifications:

The VEVOR Fire Blanket is made of premium fire-retardant fiberglass fabric, with a working temperature of up to 1022 degrees Fahrenheit (550 °C). It is 06′ x 10′ in size, and features heavy-duty brass grommets on all four sides for easy adjustment.

Performance:

This blanket provides excellent thermal protection, and is designed to protect against heat, sparks, and splatter. It is lightweight and foldable, making it perfectly portable.

Pros:

This fire blanket is 100% flame-retardant, durable, adjustable, and perfectly portable.

Cons:

The VEVOR Fire Blanket is expensive compared to other fire blankets.

2. Tonyko Fire Blanket

Tonyko Fire Blanket is made from non-flammable materials, which means that it can stand up to a lot of fire. It has a high melting point, so it will provide users with more protection.

Specifications:

The Tonyko Fire Blanket is made from a fiberglass cloth material, which is able to withstand temperatures up to 1076°F or 580°C. It is designed to smother fires quickly and easily, and can be used to prevent fires from spreading. The blanket measures 39.3” x 39.3” and has a weight of 0.52 kg.

Performance:

It is able to extinguish fires caused by grease, oil, electrical and other combustible materials.

Pros:

This product is less messy compared to traditional fire extinguishers.

It is constructed using durable, flame-retardant fiberglass material.

Cons:

This product heats up quickly.

Some users have reported allergic reactions when using it

3. Aksipo Fire Blanket

The Aksipo Fire Blanket is a fire safety tool designed to quickly and easily put out small fires. It is designed to be extra lightweight as well as easy to use, and can be hung in kitchens for easy reach in case of an emergency.

Specifications:

It is made from a premium fiberglass material and has a fire-resistance rating of up to 1022°F. It is suitable for putting out Class K fires.

Performance:

The Blanket is designed to quickly and easily put out small fires caused by combustible materials, such as grease, oil, or electrical.

Pros:

This product is designed to be easy, safe and clean to use, it comes in a small packaging, making it easy to store and transport.

No prior training is necessary to use it, making it user-friendly.

It is intended for use in small fires, as an alternative to traditional fire extinguishers.

Cons:

It has a maximum operating temperature of 550°C, which is slightly lower than similar products in the market.

4. DIBBATU Fire Blanket

The DIBBATU Fire Blanket is a safety device designed to extinguish incipient (starting) fires. It consists of a sheet of a fire-retardant material that is placed over the fire to smother it.

Specifications:

The blanket is made of high-quality materials, weighs 5.19 pounds, and measures 39 x 39 x 0.01 inches in dimensions. Its heat tolerance can hit up to 580°C and is designed to provide comfort during emergencies.

Performance:

The blanket comes with a five-year warranty, so you can have peace of mind knowing you have a blanket that is reliable and long-lasting. With its high performance, safety, and durability, the DIBBATU Fire Blanket is the perfect choice for protection from fire and heat.

Pros:

This product does not require any previous knowledge or training to use.

It is designed to be highly convenient and efficient, with a foldable structure that allows for quick release in emergency situations.

Cons:

It is not suitable for use in large-scale fire incidents like other fire blankets.

5. SKAMZ Fire Blanket

The SKAMZ Fire Blanket is a fire safety tool designed to quickly and easily put out small fires. It is made from a lightweight, yet durable fiberglass material that can withstand temperatures up to 1076°F or 580°C.

Specifications:

The blanket measures 47.24” x 47.24” and has a weight of 0.79 kg. It meets EN-18691997 specifications for cooking fire suppression.

Performance:

The fire blanket is also lightweight and easy to use, and can be hung up in just a few seconds. Plus, it’s reusable and washable, so you can be sure it will last you a long time.

Pros:

The compact design allows for convenient storage in kitchen drawers.

This product is user-friendly, no prior experience is needed to use it.

Cons:

The blanket may tear when taken out of the storage pouch

After reviewing the 05 best Fire Blankets, VEVOR Fire Blanket stands out as the top choice among all welding fire blankets on the market. With its advanced features, safety precautions, high power, and budget-friendly price point, don’t settle for just any welding fire blanket, upgrade to the best with VEVOR today!

Different Types of Welding Fire Blankets

There are several types of welding fire blankets available on the market, each with its own specific characteristics and uses. Some common types include:

Fiberglass welding fire blankets: These blankets are made from woven fiberglass fibers and are often used for general welding, cutting, and grinding applications. For example, VEVOR Fire Blanket, which is a top-performing and highly popular option in the fire safety industry. With its smooth working capabilities, it’s the perfect choice for those looking for top-of-the-line protection.

Ceramic welding fire blankets: These blankets are made from ceramic fibers and are designed for high-temperature applications, such as welding and brazing. They are extremely heat-resistant and are often used in industrial settings.

Kevlar welding fire blankets: These blankets are made from Kevlar, a synthetic fiber that is known for its high strength and heat resistance. They are often used in applications where exposure to high temperatures is expected.

Silicone coated welding fire blankets: These blankets are made of fiberglass with a silicone coating on one side which protect against sparks and spatter. They are often used in welding, cutting and grinding applications, as well as in other industrial settings.

Metalized welding fire blanket: These blankets are made of fiberglass or ceramic fiber with a metalized layer on one side, which reflects heat and are often used in applications where exposure to high temperatures is expected.

What Should You look for When Buying a Welding Fire Blanket

When buying a welding fire blanket, there are several key factors to consider to ensure that you are getting a product that will meet your specific needs and provide the protection you require. Some things to look for when purchasing a welding fire blanket include:

Temperature resistance: The most important factor to consider when purchasing a welding fire blanket is the blanket’s temperature resistance. Make sure to choose a blanket that is rated for the temperatures you will be working with.

Material: Different materials have different levels of heat resistance and durability. Fiberglass, ceramic and Kevlar are common materials used for welding fire blankets and each have their own level of protection and durability.

Size: Make sure to choose a welding fire blanket that is large enough to cover the area you will be working on.

Durability: Look for a welding fire blanket that is made from high-quality materials and is constructed to withstand the rigors of frequent use, such as VEVOR Fire Blanket, with its sleek design, exceptional durability, it’s the perfect companion in your working environment.

Versatility: Some welding fire blanket come with multiple usage, like welding, grinding and cutting, while some are specific for one usage. Consider your need before choosing which one to buy.

Certification: Look for a welding fire blanket that has been certified by a reputable testing organization, such as UL, to ensure that the blanket meets safety standards and has been tested to ensure that it will perform as expected.

Are Welding Fire Blankets Worth It?

Welding fire blankets are an essential piece of equipment for any welding professional, or anyone who performs welding as a hobby or for DIY projects. They provide a level of protection that cannot be achieved with other types of protective equipment, such as gloves or masks. Some of the crucial benefits include:

- Protection from flames and sparks

- Protection from heat

- Versatility

- Easy to use and move

- Cost-effective

FAQ’s

Q: What are welding fire blankets used for?

A: A welding fire blanket is a safety device that is used to protect people, equipment, and structures from the risks associated with welding.

Q: How are welding fire blankets used?

A: Welding fire blankets are used by draping them over the area that is being welded. This can include equipment, structures, or anything else that may be at risk of catching fire.

Q: How often should welding fire blankets be inspected and replaced?

A: Welding fire blankets should be inspected regularly for signs of wear and tear such as holes, tears, or fraying. They should be replaced if they are damaged in any way. It’s generally recommended to replace them at least every 2 years.

Arabic

Arabic Danish

Danish Dutch

Dutch English

English Finnish

Finnish French

French German

German Hungarian

Hungarian Italian

Italian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Spanish

Spanish Swedish

Swedish